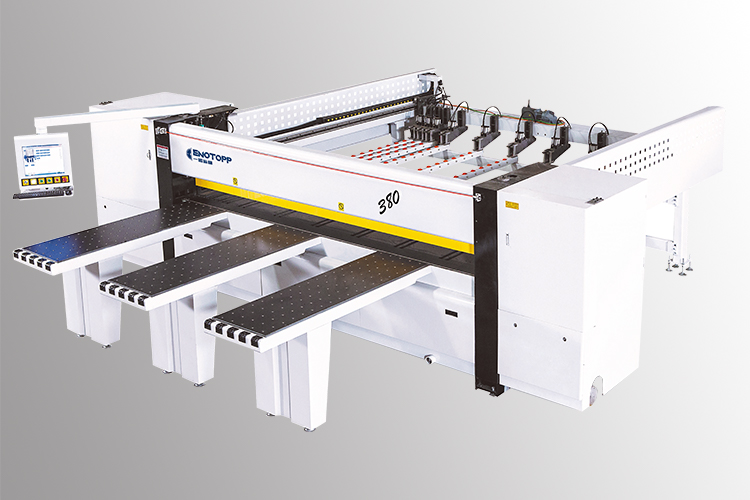

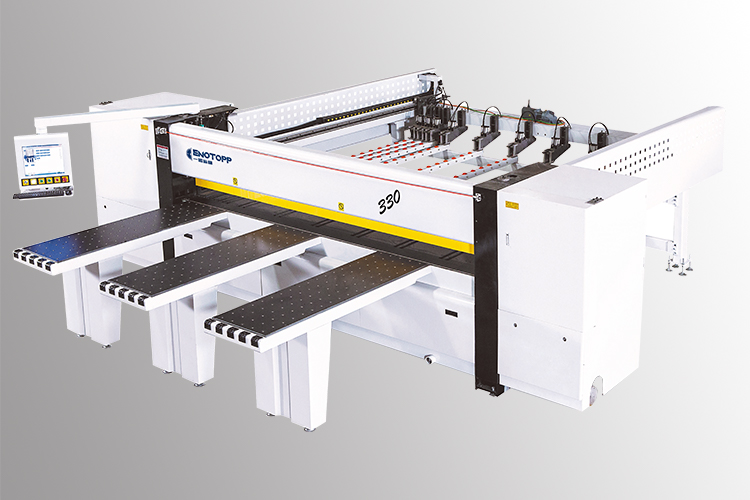

ENOTOPP 330-160 powerful angular saw computer beam saw for wood panel cutting

Brand: ENOTOPP

Model: YZJ-330-160

Payment Terms: T/T/Visa/Mastercard

Category: CNC panel saw, computer beam saw, angular saw

After-sale Service: Free professional machine operation training.

Supply Ability: 30 Sets per Month

CNC panel saw video

Computer beam saw video

Description

ENOTOPP 330-160 powerful angular saw computer beam saw is a cutting saw for mass production.

YZJ330-160 is a high-performance cutting saw. The machine is characterized by huge material throughput, technological innovation, and easy maintenance. YZJ330-160 is manufactured to meet the needs of batch cutting and maximum utilization. It is characterized by high efficiency and mass production and is also suitable for multi-shift operations.

Loading, slitting, and cross-cutting complete the cutting of the target sheet at one time. Cooperating with Computer-optimized typesetting software, it solves the problem that ordinary computer panel saws need to turn multiple times, and greatly improves production efficiency.

One vertical and horizontal angular saw is equivalent to the working efficiency of 3 to 4 computer beam saws, and the working efficiency of more than 10 sliding table saws. It can be operated by no one or one person, which greatly reduces labor costs and management costs.

Features

- Vertical and horizontal 90° sawing, automatic positioning, automatic sawing, you get the finished products with output already.

- Optimize software typesetting and material calculation, convenient and quick operation.

- Remote monitoring, remote maintenance.

- Efficient, high quality, significantly reducing production costs.

Parameters

ITEMS |

YZJ-380 |

YZJ-330 |

YZJ-280 |

|---|---|---|---|

|

Panel length |

3800mm |

3300mm |

2800mm |

|

Panel thickness |

100mm / 120mm (optional) |

100mm / 120mm (optional) |

100mm |

|

Diameter of main saw blade |

φ380-400mm |

φ380-400mm |

φ380-400mm |

|

Inner hole of main saw blade |

Φ75mm |

Φ75mm |

Φ75mm |

|

Diameter of Auxiliary saw blade |

Φ200mm |

Φ200mm |

Φ200mm |

|

Inner hole of Auxiliary saw blade |

Φ50 |

Φ50 |

Φ50 |

|

Saw seat cutting speed |

0-80m/min |

0-80m/min |

0-80m/min |

|

Saw seat reverse speed |

0-100m/min |

0-100m/min |

0-100m/min |

|

Main saw drive motor |

15kw / 18.5kw (optional) |

15kw / 18.5kw (optional) |

15kw |

|

Auxiliary saw drive motor |

2.2kw |

2.2kw |

2.2kw |

|

Saw seat servo drive |

1.3kw high torque servo |

1.3kw high torque servo |

1.3kw high torque servo |

|

Feeding servo motor |

1.3kw high torque servo |

1.3kw high torque servo |

1.3kw high torque servo |

|

High pressure blower motor |

2.2kw |

2.2kw |

2.2kw |

|

Automatic feeding speed |

0-90m/min |

0-90m/min |

0-90m/min |

|

Working table height |

920mm |

920mm |

920mm |

|

Total power |

22kw |

22kw |

22kw |

|

Working voltage |

380V/50HZ |

380V/50HZ |

380V/50HZ |

|

Working pressure |

0.6-0.8Mpa |

0.6-0.8Mpa |

0.6-0.8Mpa |

|

Machine net weight |

About 5800kg |

About 5800kg |

About 5800kg |

Applications

There are two ways of panel sizing generally used in the timber industry, the CNC nesting machine and computer beam saws. The CNC panel saws are controlled by an industrial computer, which is quite advanced and easy to operate for the users. The computer beam saws are used to process straight and batch wood panels and sheets. It has more precise cutting with a smooth surface. ENOTOPP has over 12 years of experience in designing and manufacturing panel saws, and served customers globally. The computer beam saws have been widely used for making wooden furniture in timber plants and factories.

Samples

Related Products

Contact Us

We would love to speak with you.

Feel free to reach out using the beside details.