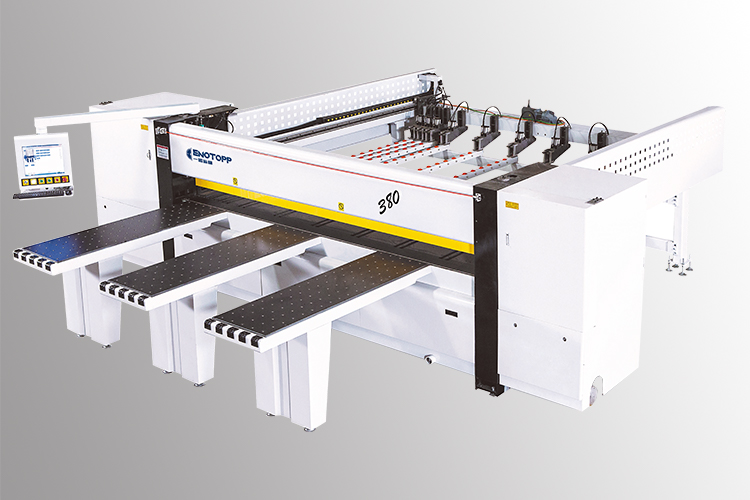

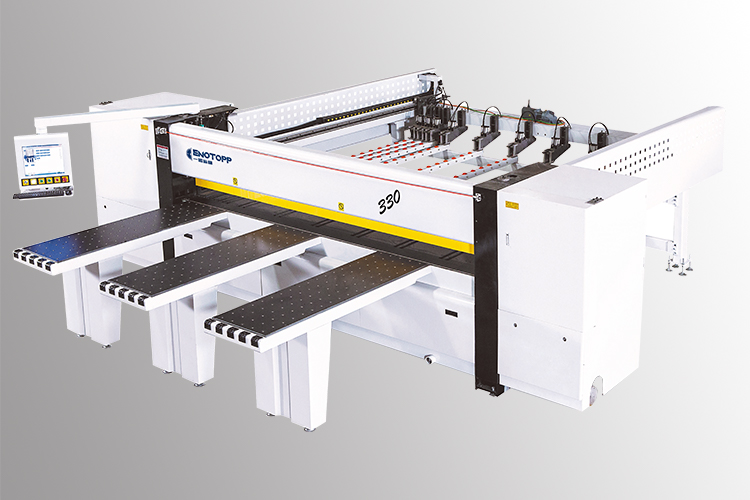

Home » Product » Customized Products » ENOTOPP export customized mirrored beam saw 330H

ENOTOPP export customized mirrored beam saw 330H

Brand: ENOTOPP

Model: YZCJ-330H

Payment Terms: T/T/Visa/Mastercard

Category: CNC panel saw, computer beam saw

After-sale Service: Free professional machine operation training.

Supply Ability: 30 Sets per Month

CNC panel saw video

Computer beam saw video

Description

ENOTOPP export customized mirrored beam saw 330H is customized and developed according to customer needs. All configurations are mirror-reversed designs of the conventional rear-loading 330H electronic saw to adapt to customers’ factory application scenarios and operational needs. 330H rear-feeding beam saws are with stable operation, high efficiency and excellent quality.

Features

– Electronic saw configuration parameters are exclusively customized according to the needs of our client.

– The entire electronic saw is a mirror-reversed configuration of the conventional rear-loading 330H electronic saw;

– Customized configuration to meet customer’s production site and operational needs;

– The racks all adopt an organized structure and all reach the ground. Stable and without deformation, there is no vibration during sawing, ensuring perfect sawing results.

– The main frame adopts a precision linear guide structure with high precision.

– The left and right beams of the manipulator are made of thick steel plates welded into an I-beam structure. They use precision linear guides for movement, making the movement smooth and precise.

– The clamping hand adopts a flat clamp, which has a strong grip and will not damage the board.

Parameters

ITEMS |

YZJ-380 |

YZJ-330 |

YZJ-280 |

|---|---|---|---|

|

Panel length |

3800mm |

3300mm |

2800mm |

|

Panel thickness |

100mm / 120mm (optional) |

100mm / 120mm (optional) |

100mm |

|

Diameter of main saw blade |

φ380-400mm |

φ380-400mm |

φ380-400mm |

|

Inner hole of main saw blade |

Φ75mm |

Φ75mm |

Φ75mm |

|

Diameter of Auxiliary saw blade |

Φ200mm |

Φ200mm |

Φ200mm |

|

Inner hole of Auxiliary saw blade |

Φ50 |

Φ50 |

Φ50 |

|

Saw seat cutting speed |

0-80m/min |

0-80m/min |

0-80m/min |

|

Saw seat reverse speed |

0-100m/min |

0-100m/min |

0-100m/min |

|

Main saw drive motor |

15kw / 18.5kw (optional) |

15kw / 18.5kw (optional) |

15kw |

|

Auxiliary saw drive motor |

2.2kw |

2.2kw |

2.2kw |

|

Saw seat servo drive |

1.3kw high torque servo |

1.3kw high torque servo |

1.3kw high torque servo |

|

Feeding servo motor |

1.3kw high torque servo |

1.3kw high torque servo |

1.3kw high torque servo |

|

High pressure blower motor |

2.2kw |

2.2kw |

2.2kw |

|

Automatic feeding speed |

0-90m/min |

0-90m/min |

0-90m/min |

|

Working table height |

920mm |

920mm |

920mm |

|

Total power |

22kw |

22kw |

22kw |

|

Working voltage |

380V/50HZ |

380V/50HZ |

380V/50HZ |

|

Working pressure |

0.6-0.8Mpa |

0.6-0.8Mpa |

0.6-0.8Mpa |

|

Machine net weight |

About 5800kg |

About 5800kg |

About 5800kg |

Applications

There are two ways of panel sizing generally used in the timber industry, the CNC nesting machine and computer beam saws. The CNC panel saws are controlled by an industrial computer, which is quite advanced and easy to operate for the users. The computer beam saws are used to process straight and batch wood panels and sheets. It has more precise cutting with a smooth surface. ENOTOPP has over 12 years of experience in designing and manufacturing panel saws, and served customers globally. The computer beam saws have been widely used for making wooden furniture in timber plants and factories.

Samples

Related Customized Woodworking Machinery

Related Computer Beam Saws

Contact Us

We would love to speak with you.

Feel free to reach out using the beside details.